Product service

Combined substation

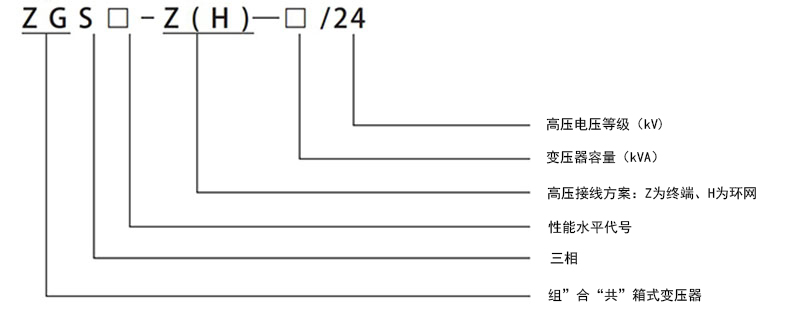

ZGS-Z(H)-24

- Description

- Data Sheet

Product Introduction

The ZGS □-24 prefabricated substation is a type of prefabricated substation (also known as the American style substation) and which is a complete set of new type power distribution equipment developed base on the American prefabricated transformers. The ZGS □-24 prefabricated substation is optimized substation with the combination of oil-immersed power transformers and the HV&LV electrical components. Through structure optimization and miniaturization of the switching equipment, the area space of the combined transformer is greatly reduced, and the volume is only equivalent to 1/3 ~ 1/5 of the European style modular transformers but keep same power capacity. The ZGS □-24 prefabricated substation has the advantages of small sizes, low noise, stable power supply, flexible installation, easy operation and has maximum using of the load of components. The system is widely used in residential quarter, commercial center, rail station, mining, airport, railway, school, hospital and high building.

Model Details

Product Structure

The ZGS □-24 prefabricated substation is a type of conventional American by zigzag structure and divided into two parts. The front part is for HV&LV front cabinet, and the 24kV HV load switch with unload tapping operating handle, plug-in fuses, pressure release valve, oil thermometer, oil level gauge, oil injection hole and oil discharge valve are included in the HV front cabinet. The oil tank with air-cooling fin, transformer windings and core, KV load switch, unload tapping switch and fuses for protection are installed in the rear part. The oil tank is full sealed structure.

The ZGS □-24 prefabricated substation also can be domino structure and the structure is divided into HV cabinet, transformer and LV cabinet.

High Voltage Transformer

The HV terminals (single route or double routes) of the ZGS Series American style prefabricated transformer fitted with high voltage bushing are used to connect elbow-type cable plug or elbow-type full insulated arresters, and enclose the charged parts into an insulated part to form an insulation structure. The terminal surface is not charged and to ensure personal safety. In case of emergency, the cable plug can pull in or pull out in charged when the transformer is full loading, since the cable plug can provide the protection of load switch. According to the customer’s requirements, the display or the fault indicator can be mounted on the cable plug.

A wall hanging is welded on the wall of the front cabinet near the high-voltage bushing, which could be used to fix plug in of the bushing support , when the plug of the cable is pulled out in charged.

Fuse

The ZGS Series prefabricated substation adopts two sub-series protection of the plug-in fuse and back-up current-limiting fuse, this type of protection has the advantages of advanced, economic, reliable and easy operation. The Plug-in fuse is used for over-current when small-scale breaking (including the short-circuit fault at the LV side). In case of the transformer overload and high temperature, the fuse is mainly used to protect the combined transformer. The backup current-limiting fuse is used for the wide range fault current breaking, mainly the short-circuit fault at the HV side of the transformer, and can shut the transformer with faults, and protect the HV transmission line.

24KV Load Switch

The 24kV oil-immersed load switch is a three-phase linked switch and can be operated as the springs, this type load switch can be used for breaking and closing operation. The load switch has two types of two position structure or four position structure. The two position switch is used for the terminal type power supply, and the four-position switch is used for the ring network or dual power supply.

Low voltage interval

In the LV interval, there are outgoing terminals. According to the requirements, there could be the LV main breaker and branch circuit breaker, LV ammeter and voltmeter, and automatic reactive power replenish equipment fixed in the cabinet. In accordance with the user's requirements, the axial flow fan could be installed at the top of the LV cabinet, and automatically controlled equipment will be used to control the air cooling of the cabinet. The integrated distribution tester with the function of telemetry and remote information and supplemented with low-voltage and under-voltage control device could be fixed according to the requirements. The protection of voltage loss and single-phase under- voltage could be realized to avoid damage to transformers and electrical loads.

Product advantages

Fully Function and Reliable

The load current can be cut off, the load current can be full range protected, the power supply can be provided by the cable connection of ring network (dual powers) and terminals, and could be used as the basic ground substation construction.

Low investment, space saving, easy installation, and speed up the power supply

Low investment:

compare with the European style and normal substation with foundation, the investment for the ZGS series is much cheaper.

Easy installation:

Mostly works have been finished in factory, and few works need to be done on site like four bolts’ fasten, cable and elbow arrester installation

Fast power supply speed: the substation can be designed and produced with the information of capacity of the transformers, even if the electric parameters such as breaking current, dynamic stability and relay protection are not necessary to be provided for ordering.

Safe and Reliable of Power Supply

The ZGS Series is fully closed design with three-point grounding. There are no conductive components on the surface of the shell, and don’t pay attention to the insulation distance, which make the safety could be ensured. The high voltage wring are all fully insulated by the elbow-type cable head and can be easy to plug, The surface can be touched as not charged. The main part of insulated joystick can be easily operated which ensure personal safety.

Simple and Convenient Maintenance

The structure of plug type fuse, cable plug and the elbow-type lightning arrester make the replacement very convenient. The fully sealed structure avoids the connection between the insulation oil and the air, which make the transformer free of the maintenance.

Ordering instructions

The information need to be provided by the customer to the manufacturer.

A. Product Model

B. Operation Conditions

C. Transformer Model and Capacity

D. Cable Installation Solution, and Electrical Components’ Model and Parameters

E. Shell Color Code

F. If any other requirements, the clients can provide to manufacturer while place the order.

-

Items

Unit

Parameter

Rated Voltage

HV side

10

0.410

LV side

0.4

Max. working voltage

KV

12

Rated Frequency

HZ

50

Rate capacity

KVA

100.125.160.200.250.315.400.500.630

800.1000.1250.16001 minute working frequency withstand voltage

KV

42(exclude the transformer)

35(include the transformer)BIL impact withstand voltage

KV

75

Cooling Solution

Oil-immersed and self-cooling

Unload voltage adjustment

KV

±2×2.5 %

Working Temperature

℃

﹣45~+40

The allowed max. raised temperature on the top layer of the transformer oil tank

K

≤55

The allowed max. raised temperature of transformer LV winding

K

≤65

The allowed max. raised temperature of transformer HV winding

K

≤65

Noise Level

dB

≤55

Protection Grades

IP

33